Can a Beginner Install Vinyl Plank Flooring?

Vinyl plank flooring has gained popularity for its durability, affordability, and ease of installation. But can a beginner really handle installing vinyl plank flooring? The answer is yes—if you're equipped with the right tools and guidance, vinyl plank flooring is one of the more accessible DIY flooring options available. Here’s a comprehensive guide to help beginners install vinyl plank flooring successfully.

Understanding Vinyl Plank Flooring

Types of Vinyl Plank Flooring

Before diving into installation, it’s important to understand the different types of vinyl plank flooring. The most common types include:

- Rigid Core Vinyl Planks: These are sturdy, durable, and mimic the look of hardwood floors. They are available in click-lock designs, making installation easier for beginners.

- Luxury Vinyl Planks (LVP): This type offers more flexibility and comes in both click-lock and glue-down versions. It provides an upscale look at a more affordable price than hardwood.

Why Vinyl Plank Flooring is Beginner-Friendly

Vinyl plank flooring is ideal for beginners because of its ease of installation. Most types, especially those with click-lock mechanisms, require no glue or nails. The planks fit together like puzzle pieces, and you can even install them over existing floors in many cases. Additionally, vinyl flooring is highly durable and waterproof, making it suitable for a variety of rooms.

Tools and Materials Needed

Essential Tools for Installation

Here are the basic tools required for installing vinyl plank flooring:

- Utility knife: Used for cutting planks to size.

- Measuring tape: To measure the room and ensure accurate cuts.

- T-square: For cutting planks at straight angles.

- Rubber mallet: Helps lock planks together in click-lock systems.

- Spacers: Ensure consistent gaps between the planks and walls for expansion.

Additional Tools for a Professional Finish

While the basic tools will get the job done, a few additional tools can help improve the quality of your installation:

- Pull bar: Helps pull together planks in tight areas.

- Saw: For more precise cuts, especially around door frames and vents.

- Floor roller: Ensures proper adhesive contact if you’re using glue-down planks.

Preparing the Subfloor

Cleaning and Leveling the Subfloor

A clean and level subfloor is critical to a successful vinyl plank installation. Begin by sweeping or vacuuming the area to remove debris. Then, check the floor for any bumps or uneven spots:

- Concrete Subfloors: Fill any cracks or low spots with a patching compound and sand down high points.

- Wood Subfloors: Ensure nails are driven below the surface and smooth any rough patches with sandpaper.

Fixing Common Subfloor Issues

If the subfloor is uneven or has moisture issues, your flooring won’t last long. Moisture problems should be addressed by sealing the floor, especially for rooms like basements or bathrooms. Consider using an underlayment to help smooth out imperfections in the subfloor and provide a cushion for the vinyl planks.

Planning the Layout

Measuring the Room

Accurate measurements ensure that you purchase the right amount of vinyl planks and avoid waste. Measure the length and width of the room, then multiply the two numbers to find the square footage. Add 10% extra for cutting errors and waste.

Planning the Plank Direction

Most professionals recommend laying planks parallel to the longest wall or in the direction of natural light. This provides a more aesthetically pleasing look and can make a small room appear larger.

Installing Vinyl Plank Flooring

Step-by-Step Installation Guide

- Acclimate the Planks: Let the vinyl planks sit in the room for 48 hours before installation. This allows them to adjust to the room’s temperature and humidity.

- Start with the First Row: Begin by placing spacers along the wall to leave a gap for expansion. Lay the first plank in the corner with the groove side facing the wall.

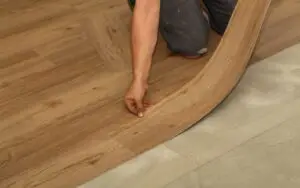

- Click-Lock or Glue-Down: For click-lock planks, angle the next plank’s tongue into the previous plank’s groove and press down until it locks into place. For glue-down planks, apply adhesive to the subfloor and press the planks firmly into place.

- Cut Planks to Fit: When you reach the end of a row, measure and cut the plank to fit. Use a utility knife for simple cuts or a saw for more precision around obstacles.

- Stagger the Seams: To achieve a natural wood look, stagger the seams of each row so they don’t line up with the previous row.

Installing Around Corners and Vents

Trimming planks around corners or floor vents can be tricky for beginners. Measure the area carefully, cut the plank with a utility knife or saw, and fit the plank snugly around the obstacle.

Common Mistakes to Avoid

Overlapping Joints or Uneven Planks

Ensure that each plank is properly locked into place to avoid uneven flooring. Overlapping joints or gaps between planks can lead to a poor finish and even floor damage over time.

Incorrect Use of Adhesive or Underlayment

If you’re using glue-down planks, follow the manufacturer’s instructions for adhesive application. Too much or too little glue can cause issues. For floating floors, ensure the underlayment is smooth and properly installed to prevent noise or discomfort when walking.

How to Trim and Finish the Installation

Trimming Planks for a Perfect Fit

Use a sharp utility knife or saw to trim the last row of planks to fit snugly against the wall. Always leave a small gap (about 1/4 inch) between the planks and the wall for expansion.

Installing Baseboards and Transition Strips

Once the planks are in place, remove the spacers and install baseboards to cover the expansion gap. Use transition strips at doorways and between different types of flooring for a seamless finish.

Caring for Your Vinyl Plank Floor

Maintenance Tips

Vinyl plank flooring is relatively low-maintenance, but proper care can extend its lifespan. Clean the floor regularly using a broom or vacuum designed for hard surfaces. Avoid using abrasive cleaners or tools that could scratch the surface.

Fixing Scratches or Damage

Minor scratches can be buffed out using a vinyl floor repair kit. For deeper damage, replacing individual planks is simple—just remove the damaged plank and click a new one into place.

DIY vs. Hiring a Professional for Vinyl Plank Flooring

DIY Challenges

While vinyl plank flooring is beginner-friendly, there are potential challenges. Subfloor preparation can be more complicated than expected, and making precise cuts around obstacles like door frames may require specialized tools. Mistakes can lead to wasted materials and a subpar finish.

Benefits of Hiring a Professional

Hiring a professional ensures the job is done right the first time. Professionals have the tools and experience to install flooring quickly and accurately. They can also offer warranties on their work, giving you peace of mind. While DIY installation may save money upfront, professional installation can prevent costly mistakes in the long run.

Case Study: DIY vs. Professional Installation

For a 200-square-foot room, DIY installation costs might total around $300 for materials and tools. Professional installation for the same space could cost around $500. However, the professional installation guarantees a flawless finish, which can increase the value of your home.

Installing vinyl plank flooring is certainly within the reach of a beginner, but if you're unsure about the process or run into issues, hiring a professional can save time, effort, and money in the long term. Ready to upgrade your floors? Contact a professional installer today!

Understanding the Basics of Wood Floor Sanding

Wood floor sanding is an essential process in refinishing wooden floors. It involves removing the top surface of the wood to eliminate imperfections, scratches, and old finishes. Sanding prepares the floor for staining and sealing, ensuring a smooth, flawless finish. Without proper sanding, refinishing would be less effective, and the floor might not achieve the desired look or durability.

What is Wood Floor Sanding?

Wood floor sanding is a method of using abrasive materials to strip off the damaged or worn-out surface of wooden floors. This process removes deep scratches, dents, and old varnish, creating a clean slate for refinishing. The sanding process involves multiple stages using different grit sandpapers, starting with coarser grits and progressing to finer grits for a polished finish.

Importance of Sanding Before Refinishing

Sanding is crucial because it provides a smooth and even surface for new finishes like stains or sealants to adhere properly. Without sanding, uneven spots, stains, and surface scratches would be visible, reducing the overall appearance of the refinished floor. Sanding also opens the wood pores, allowing the stain to penetrate deeper and ensuring the finish lasts longer.

Key Benefits of Professional Sanding

- Smooth and consistent finish

- Proper removal of deep scratches and dents

- Ensures a long-lasting, high-quality refinish

- Dust-free or reduced dust with professional-grade equipment

Types of Wooden Floors That Need Sanding

Not all wooden floors require sanding. Solid hardwood floors can withstand multiple sandings due to their thickness, while engineered wood floors can be sanded once or twice before the top layer wears out. Laminated floors, on the other hand, cannot be sanded and would need replacement instead of refinishing.

Tools and Equipment Used in Wood Floor Sanding

Professional wood floor sanding requires specialized tools designed for effective, smooth, and efficient sanding. Using the right equipment ensures that the sanding process is done correctly, reducing the risk of uneven surfaces or damaging the wood.

Essential Sanding Tools for Professionals

- Drum Sander: A powerful sander used for heavy-duty work on larger areas.

- Orbital Sander: Used for lighter sanding tasks or finishing edges and corners.

- Edger: A smaller machine that sands the areas along walls and corners where larger sanders can't reach.

The Role of Floor Sanders and Buffers

Floor sanders are the main tools used in the sanding process. They remove the top layer of the floor, leaving behind a smooth, clean surface. Buffers, on the other hand, are used after sanding to smooth out any remaining imperfections and prepare the floor for finishing.

Comparing Drum Sanders vs. Orbital Sanders

- Drum Sanders: Ideal for aggressive sanding and quickly removing old finishes.

- Orbital Sanders: Better for fine sanding and providing a smoother finish.

Preparing Your Wooden Floors for Sanding

Proper preparation is essential before starting the sanding process. Preparing the floor ensures that the sanding is done evenly and reduces the chances of damaging the wood.

Cleaning and Inspecting the Floor

Before sanding, the floor must be thoroughly cleaned to remove any dirt, dust, or debris that can interfere with the sanding process. It’s also important to inspect the floor for loose boards, nails, or deep scratches that need to be addressed before sanding begins.

Dealing with Gaps, Nails, and Imperfections

If there are any gaps or loose nails, they should be fixed before sanding. Nails should be countersunk to avoid damaging the sanding equipment. Gaps between the boards can be filled with wood filler, which will be sanded down to create an even surface.

How to Address Common Floor Problems Before Sanding

- Loose boards: Secure them with nails or glue.

- Deep scratches: Use wood filler to level the surface.

- Nail heads: Hammer them below the surface to avoid damaging the sander.

The Professional Sanding Process Explained

Sanding wooden floors involves a series of steps, starting with rough sanding and progressing to finer sanding for a smooth surface. Professionals follow a systematic process to ensure an even finish.

Step-by-Step Guide to Sanding Wooden Floors

- Coarse Grit Sanding: Start with a coarse grit sandpaper (usually 36-40 grit) to remove the old finish and even out the floor.

- Medium Grit Sanding: Move to medium grit (60-80 grit) to smooth the surface further.

- Fine Grit Sanding: Finish with fine grit sandpaper (100-120 grit) to create a smooth, polished surface.

Starting with Coarse Grit Sanding

Coarse grit sandpaper is essential for removing deep scratches, dents, and old finishes. It’s the first step in leveling the floor and preparing it for the finer sanding stages.

Moving to Finer Grit for a Smooth Finish

Once the coarse sanding is complete, finer grit paper is used to smooth out the surface. This step ensures that the floor is ready for refinishing and provides an even, polished appearance.

Dust-Free Sanding: What You Need to Know

Dustless sanding systems significantly reduce the amount of dust generated during the sanding process. While not entirely dust-free, these systems use advanced vacuums attached to sanding machines to capture most of the airborne particles, making the process cleaner and safer.

DIY Wood Floor Sanding vs. Professional Services

While DIY sanding might seem like a cost-saving option, it comes with risks and challenges. Hiring a professional ensures high-quality results, reduced mistakes, and a longer-lasting finish.

Risks of DIY Sanding

- Uneven sanding: Inconsistent pressure can lead to uneven surfaces.

- Over-sanding: Removing too much wood can damage the floor permanently.

- Incorrect equipment usage: Professional sanders use specialized tools for a reason.

Mistakes to Avoid When Sanding Wooden Floors Yourself

- Skipping grits: Not following the proper sanding progression can leave visible scratches.

- Using low-quality sandpaper: Cheap sandpaper can wear out quickly and damage the floor.

Benefits of Hiring Professional Floor Sanders

Hiring professionals ensures the use of high-quality equipment, correct sanding techniques, and a dust-free process, resulting in a perfectly smooth and even surface.

Case Study: How a Pro Saved a Damaged Floor

A homeowner attempted to sand their floor but over-sanded certain areas, creating dips and uneven spots. A professional sanding service was able to repair the damage, restore the floor’s appearance, and refinish it for a flawless look.

How Professionals Ensure a Smooth Finish

After sanding, professionals focus on buffing and polishing to ensure the floor is ready for refinishing. This additional step helps achieve a uniform, professional-grade finish.

Buffing and Polishing After Sanding

Buffing smooths out any remaining imperfections left from sanding. Polishing prepares the surface for stains and sealants, ensuring a perfect finish.

How Sanding Prepares the Floor for Refinishing

Sanding opens the wood’s pores, allowing stains to penetrate evenly and adhere better. It ensures that the finish will last longer and protect the wood from wear and tear.

Why Proper Sanding Ensures Longer Floor Life

Properly sanded floors allow the finish to bond with the wood better, making the floor more resistant to damage and extending its lifespan.

Cost of Wood Floor Sanding Services

The cost of professional sanding varies based on several factors, including the size of the floor, the condition of the wood, and the type of finish desired.

Factors That Influence Sanding Costs

- Material type: Some woods require more delicate sanding.

- Floor size: Larger areas require more time and materials.

- Condition of the floor: Damaged floors may need more extensive sanding.

Material, Size, and Condition Considerations

Professional sanders will assess the condition of the floor and recommend the best sanding approach. This ensures the cost reflects the amount of work needed.

Why Professional Sanding Offers Better Value Over Time

Although DIY sanding might seem cheaper upfront, professional services offer better value by providing high-quality results that last longer and protect your floor from future damage.

Refinishing Wooden Floors After Sanding

After sanding, refinishing involves applying stains and sealants to protect the wood and enhance its appearance.

Applying Stains and Sealants for Durability

A stain can enhance the wood’s natural beauty, while sealants provide protection against wear and moisture. Professionals apply these finishes evenly to ensure long-lasting results.

Choosing the Right Finish for Your Wooden Floor

Different finishes offer varying levels of durability and sheen. Water-based polyurethane, oil-based finishes, and wax are some popular options, each offering unique benefits.

How Professional Refinishing Extends Floor Longevity

Professionals know how to apply finishes properly to ensure maximum protection and aesthetic appeal. This extends the life of the wood and keeps it looking fresh for years.

Common Mistakes in Wood Floor Sanding

Even small mistakes during sanding can have significant consequences. Over-sanding, for instance, can permanently damage the floor, while inconsistent sanding may lead to an uneven finish.

Over-Sanding and Its Dangers

Over-sanding can thin the wood, making it more prone to damage. Professionals avoid this by using the right techniques and equipment.

Inconsistent Sanding: Why Professional Skills Matter

Inconsistent sanding leaves visible marks and uneven surfaces. Professionals use systematic sanding techniques to achieve a flawless finish every time.

Professional Sanding Services vs. DIY: The Final Comparison

When comparing DIY sanding to professional services, it’s clear that professionals provide better results in terms of time, quality, and safety.

Time, Quality, and Safety: Why Choose Pros?

Time:

Professionals complete the job faster and with better results.

- Quality: Pros use top-tier equipment and techniques.

- Safety: Dustless sanding systems protect your health and home.

Case Study: The Difference a Professional Service Makes

In a recent case, a professional sanding service transformed a worn-out, scratched floor into a beautifully refinished surface, saving the homeowner time and money compared to a DIY attempt.