Introduction to Tiling Best Practices

Tiling is both an art and a science. By adhering to key best practices, you can achieve a professional-quality finish that enhances the durability and appearance of your tiled surfaces. Whether you’re tiling floors, walls, or backsplashes, following these golden rules ensures a flawless result.

Rule #1: Proper Surface Preparation

Preparing the surface is the foundation of successful tiling.

Cleaning the Subfloor

- Remove dirt, grease, and old adhesives.

- Vacuum or sweep thoroughly to ensure no debris is left.

Leveling the Surface

- Use a leveling compound to fix uneven areas.

- Check the surface with a level to avoid tiles shifting or cracking.

Rule #2: Choosing the Right Adhesive

Selecting the correct adhesive ensures a strong bond between the tiles and the surface.

Types of Adhesive

- Thin-set mortar for ceramic or porcelain tiles.

- Pre-mixed mastic for lightweight wall tiles.

Application Tips

- Spread adhesive evenly using a notched trowel.

- Work in small sections to prevent it from drying too quickly.

Rule #3: Planning the Tile Layout

A thoughtful layout minimizes waste and ensures symmetry.

Dry-Laying Tiles

- Place tiles without adhesive to visualize the layout.

- Adjust starting points to avoid thin slivers at the edges.

Using Guidelines

- Snap chalk lines or use a laser level for accuracy.

- Focus on high-visibility areas for the best alignment.

Rule #4: Maintaining Consistent Spacing

Consistent spacing is crucial for aesthetic appeal and grout durability.

Using Tile Spacers

- Insert spacers between tiles to maintain even gaps.

- Choose the appropriate spacer size based on tile dimensions.

Checking Alignment

- Use a level to verify tiles are aligned horizontally and vertically.

- Make adjustments before the adhesive sets.

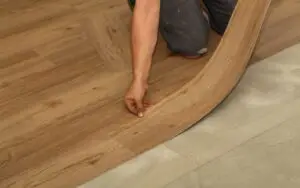

Rule #5: Accurate Tile Cutting

Cutting tiles precisely ensures a polished look around edges, corners, and obstacles.

Measuring and Marking

- Measure the space carefully and mark tiles with a pencil.

- Double-check dimensions to reduce errors.

Cutting Techniques

- Use a manual tile cutter for straight cuts.

- For curves or notches, a wet saw or tile nippers are ideal.

Rule #6: Grouting and Cleaning Tiles

Grouting not only fills gaps but also stabilizes the tiles.

Applying Grout

- Mix grout to a paste-like consistency.

- Use a grout float to press grout firmly into the joints.

Cleaning Excess Grout

- Wipe tiles with a damp sponge to remove residue.

- Avoid removing grout from the gaps during cleaning.

Rule #7: Sealing for Longevity

Sealing enhances the durability and appearance of your tiled surface.

Why Seal?

- Protects grout from moisture and stains.

- Extends the life of tiles, especially in wet areas.

Sealing Process

- Apply sealant with a brush or sponge.

- Allow it to dry fully before using the tiled area.

Common Tiling Mistakes to Avoid

Even experienced DIYers can fall into common pitfalls:

- Skipping surface preparation: Leads to uneven tiles and cracking.

- Inconsistent adhesive application: Causes weak tile bonds.

- Incorrect spacing: Results in uneven grout lines and alignment.

DIY vs Professional Tiling Services

While DIY tiling can be cost-effective, it carries risks that can lead to costly repairs.

Risks of DIY Tiling

- Misaligned layouts due to inexperience.

- Poor cuts around edges, affecting aesthetics.

Benefits of Professional Installation

- Access to specialized tools and techniques.

- Expertise in handling complex layouts and challenging surfaces.

Example: A homeowner’s DIY tiling job resulted in uneven tiles and cracked grout within months. Hiring a professional to redo the work ensured a long-lasting and visually perfect installation.

Avoid costly mistakes and achieve a flawless finish by hiring professional tiling services today!

FAQs & Answers

A smooth, clean surface prevents tile cracking and ensures longevity.

Use spacers consistently and double-check with a level.

A manual tile cutter for straight cuts; a wet saw for curves.

After grout has fully cured, typically 48-72 hours post-application.

DIY is possible, but professional tilers guarantee precision and durability.